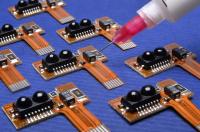

Designed to improve reliability, Master Bond’s line of epoxy underfill compositions offer excellent underfill to die passivation as well as outstanding adhesion to a variety of substrates. They improve mechanical support, lower strain on solder joints and provide superior protection from moisture.

Applications for Epoxy Underfill Encapsulants

- Flip chip devices

- Ball grid arrays

- Chip scale packaging

Advantages of Master Bond Underfill Systems

Both flowable and non-flow systems are available for use. Additionally, to improve efficiency of production snap cure and reworkable systems have been introduced. The key properties of theses systems include:

- High purity

- Low stress

- High adhesion

- Low coefficient of thermal expansion (CTE)

- Low outgassing

- High glass transition temperature (Tg)

- High Young’s modulus

- Moisture resistance

- Short cure cycle

- Structural stability

- Thermal cycling resistance

- Shock and vibration resistance

Our Most Popular Flip Chip Underfill Systems

|

EP3UF One component epoxy for bonding and underfill applications. Thermally conductive/electrically insulative. Meets NASA low outgassing specifications. High mechanical strength properties. Ultra fine particle sizes lowers thermal resistance. Convenient processing at moderate temperatures. Serviceable from -60°F to +250°F. |

|

EP4UF-80 One component, low viscosity epoxy primarily for underfill applications. Not premixed and frozen, with unlimited working life at room temperature. Cures at elevated temperatures with a minimum of 80°C. The service temperature range is -50°C to +150°C. |

|

UV22DC80-1Med Dual cure system with UV and heat curing mechanisms. Cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Serviceable from -60°F to +350°F. |

|

EP114 Two component nanosilica filled epoxy for potting, coating and sealing. Optically clear. Low shrinkage. Superior electrical insulation properties. Toughened system. Successfully tested for 1,000 hours 85°C/85% RH. Serviceable from -100°F to +450°F. |

|

EP4NS-80 One component, optically clear, exceptionally low viscosity epoxy for bonding and sealing. Typically, curing is at 80°C for 2-4 hours, and for full optimization of properties, this should be followed by 110-125°C for 1-2 hours. Unlimited working life at room temperature. Excellent dimensional stability, low CTE and minimal shrinkage upon curing. |